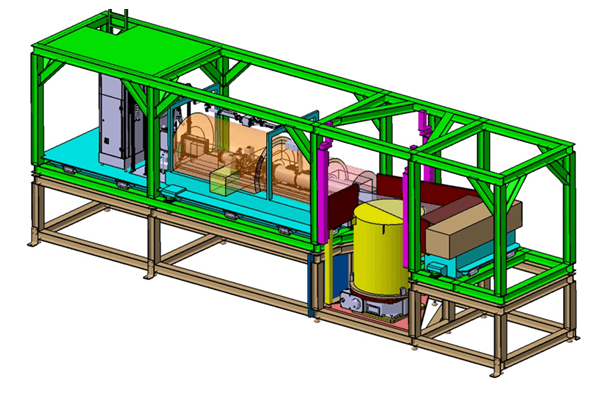

Conception

SOLUTIONS

Feasibility studies / Optimisation

Manufacturing strategy / Cost assessment

Technological monitoring / Prototyping

BENEFITS

Integration of constraints: manufacturing, assembly and testing, commissioning and maintenance

Optimisation of manufacturing costs and lead-times

Assessment of costs and lead-times

Specifications

SOLUTIONS

Specification writing / Evaluation

Proficient application of codes & standards: RCCM-Rx, ASME...

Supplier identification

Selection-criteria definition

BENEFITS

Reduction of risk of misinterpretation and application of requirements

Alignment of stakeholders

Optimised industrial strategy

Manufacturer selection

SOLUTIONS

Supplier evaluation: means, capacity, references

Offer analysis (technical, cost, lead-time)

BENEFITS

Product quality / Competitive costs

Reliability of deadlines

Long-term partnership

Reduction of risk of conflict (amendments, delay…)

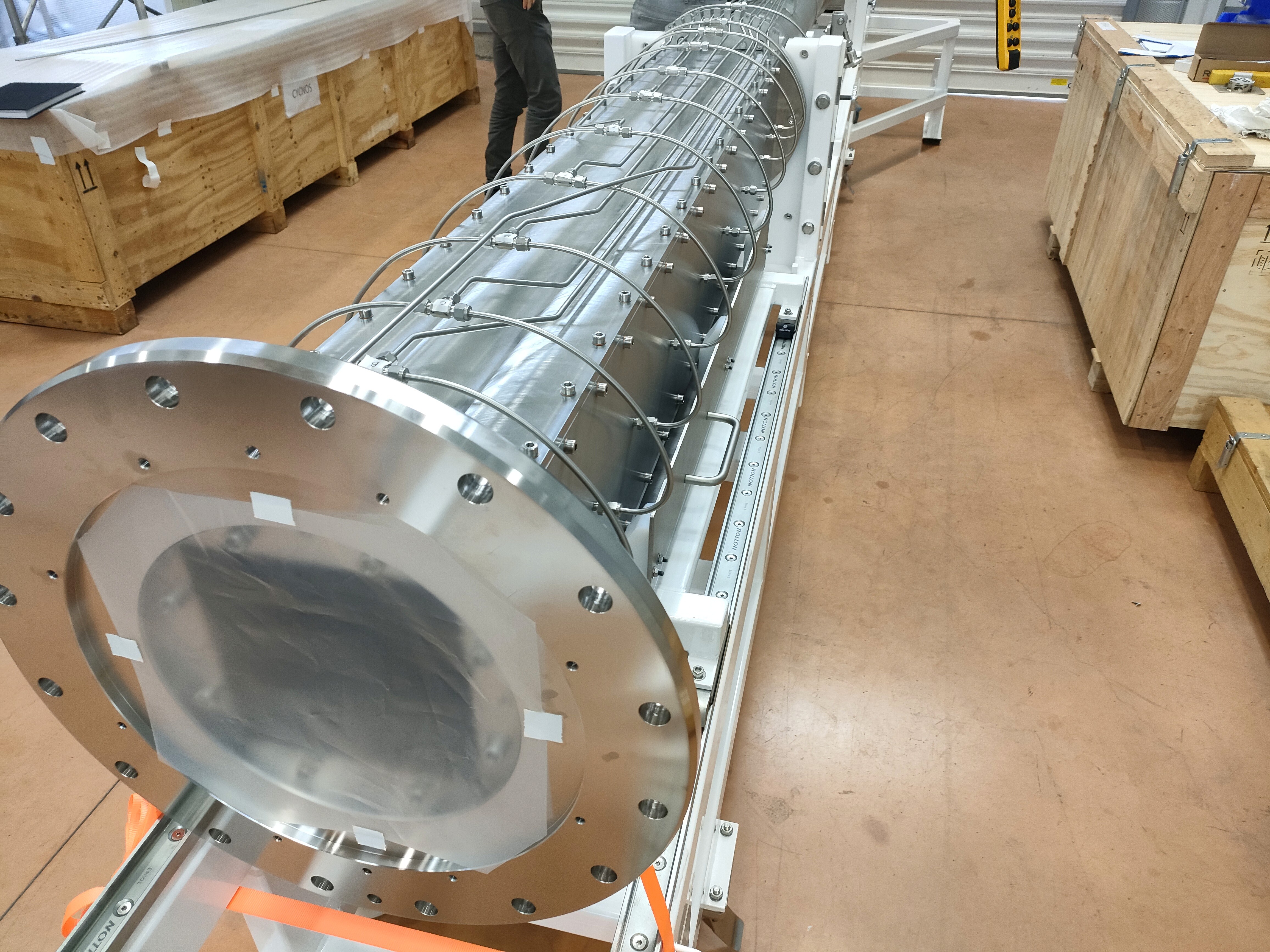

Manufacturing

SOLUTIONS

Review of manufacturing and control documentation

Partial or full follow-up of manufacturing

BENEFITS

Documents compliant with your requirements and standards/codes

Strengthen your teams / Optimise your resources

Management of manufacturing contingencies

Guarantee final conformity

Testing, factory site and commissioning

SOLUTIONS

Follow-up of factory tests and commissioning

Feedback on manufacturing cycle

BENEFITS

Final conformity

Optimisation of your concept for industrialisation